MK Magnetics, Inc. is a leading manufacturer and supplier distributing quality tape wound magnetic cores designed to meet your specific requirements. With our in-house capabilities and years of expertise, we can deliver the magnetic core you need for your diverse projects.

Our team of expert engineers has been creating cores for many years, manufacturing different types of tape-wound soft magnetic cores because of the variety of customer requirements. With that said, we have an extensive manufacturing process and strict quality control that adheres to the requirements of ISO 9001.

Customized Tape-Wound Built According to Your Needs

We have a complete line of tape-wound soft magnetic cores made from different materials. These materials ensure you receive a product made to last and provide you with the performance you need.

Our expert engineering team can provide support in your product design and other areas, such as providing suitable materials based on your specific needs. We understand that every application has its requirements, so we offer customized solutions or modifications to our line of core models to meet your exact requirements. The materials we work with include the following:

- Nanocrystalline: These are polycrystalline materials made with crystallite size that are only a few nanometers in size. These materials fill the gap between amorphous materials without any long-range order and conventional coarse-grained materials. Cores made with nanocrystalline materials offer low power loss, high saturation, and permeability.

- Amorphous materials: These are materials with disordered atomic structures. It’s glass-like but also has non-crystalline alloys. Furthermore, they have outstanding magnetic properties with high permeability, high saturation, low core loss, and high flux density.

- Grain-oriented silicon steel: These have magnetic properties developed in the rolling direction. It has high saturation and magnetic flux density and, in most cases, offers an affordable option compared to other materials.

- Non-oriented materials: These have magnetic properties similar in all directions.

- 50% and 80% Nickel alloys: These are our most traditional materials that offer better ductility and resistance to harsh environmental conditions with better thermal stability than amorphous and/or nanocrystalline magnetic materials.

- Cobalt alloys: Supermendur® is a cobalt iron material with low core loss and high flux density. It’s the ideal option for industries where mass and size are considered.

The Next-Generation Material at Your Disposal

We produce magnetics cores using the best next-generation material, which is nanocrystalline. Our nanocrystalline core is used in numerous applications due to its high permeability and low core losses in comparison with other alloys. Furthermore, it offers the best magnetic performance from low to high frequencies.

CASE STUDIES

Gapped Toroid

Ultra-Low Loss

Amorphous

Cores

Long

Nanocrystalline

Bars

Custom

Pulse Cores

Custom

Magnetic

Products

Energy

Harvester

Cores

Advanced

Nanocrystalline

Cores

Tape Wound Soft Magnetic Cores Built to Your Requirements

We offer a complete line of tape wound soft magnetic cores manufactured from a variety of materials including grain-oriented silicon steels, 50% and 80% nickel alloys, amorphous material, cobalt alloys, and the newest, next-generation material: nanocrystalline. Offering both standard and highly specialized custom core products, we look forward to providing our customers with the highest quality and craftsmanship available in every core we produce.

Contact MK MagneticsINDUSTRIES SERVED

MK Magnetics, Inc. provides the highest quality products and services for a wide range of markets & industries: Aerospace, Smart Grid, Renewable Energy, Energy Storage, Oil & Mineral Exploration, Medical Imaging, High Frequency Applications, and more.

Industries We Serve

Since we’re one of the leading and most reputable sources of magnetic core products, we ensure they’re made with the highest standards. Our high-caliber work guarantees that every industry uses our products according to their intended application and purpose.

Aerospace

The aerospace industry is one of the most demanding industries requiring magnetic cores. They are used for various aerospace applications, such as transformers that facilitate the power supply, electrical systems filtrations, and other systems.

Smart Grid

A Smart grid requires a highly efficient core for energy harvesting to power electronic Smart Sensors. Our cores are used for current sensors. However, choosing a material that can withstand these demanding environments efficiently is necessary to achieve the desired results.

Renewable Energy

Since renewable energy refers to the natural resources used as an energy source, you must choose the proper tape-wound magnetic cores for optimum efficiency. One of the many applications used are transformers and filters.

We can support renewable energy with our cutting-edge technology. In addition, we ensure that our products achieve optimum performance for better energy output.

Energy Storage

Energy storage is a critical system for the efficient use of renewable energy; these systems require efficient power transformers and filter inductors that utilize magnetic cores from many alloys, depending on the specific needs of the system.

Oil & Mineral Exploration

Transformers are utilized in the oil and mineral industry since they provide energy to the devices used for exploration and directional drilling. our tape wound magnetic cores are used for transformers, antennas, magnetometers, and other applications.

Medical Imaging

Magnetic cores are used in medical imaging devices such as X-rays, MRI, CT scanners, and other imaging devices.

Thanks to our unique customizable processes and capabilities, MK Magnetics can provide solutions that set MK Magnetics apart. Our magnetic cores are an excellent component for the applications listed above and other types of medical applications where a tape wound core is necessary. can proc

Common Applications of Our Tape Wound Soft Magnetic Cores

Since our cores are used in many different industries, the applications are also diverse. In addition to the industries mentioned, our cores are also utilized in high-frequency applications, such as Capital items, plasma energy, induction, inverters, converters, military hardware, directed energy systems, fusion power, prototyping, and new technologies.

Other typical devices and devices and applications for our cores are as follows:

- Converters

- Inverters

- Transformers

- Chokes

- Electric motors

- Sensors

- Induction devices

These are only some common applications for which our magnetic cores are used. So if you need tape-wound magnetic cores, we guarantee that our products are of superior quality and reliability.

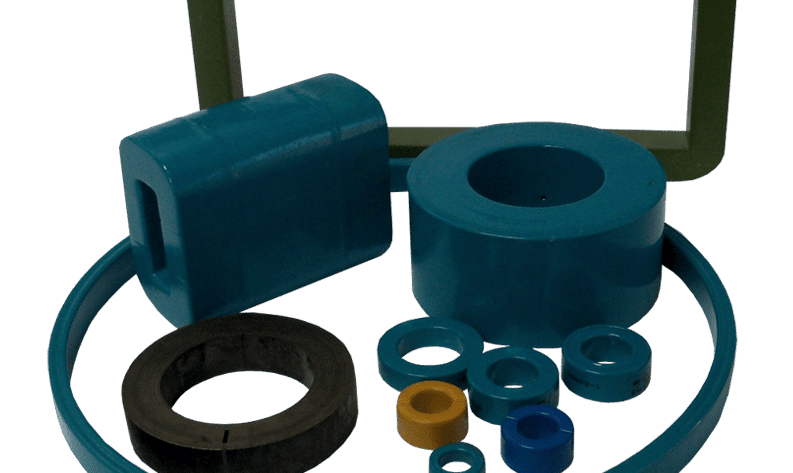

An Extensive Range of Configurations is Available

We also offer core configurations essential for superior performance reliability. Our products offer core configurations as follows:

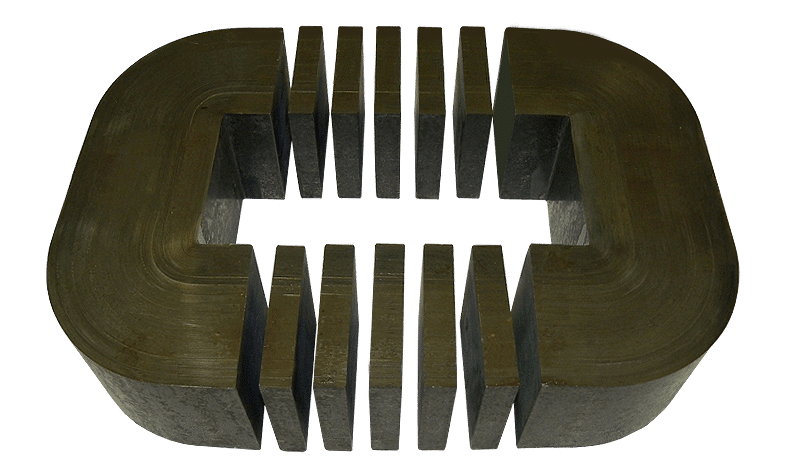

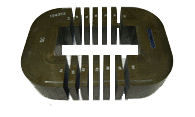

- C-cores

- E-cores

- Bars/block

- Toroidal-shaped cores, including cased and epoxy coating.

- Gapped toroids

- Other custom configurations.

We can produce cores that can be hundredths of a pound to several thousand pounds, so size is not an issue for us. Whatever size you need, we can manufacture it to your specifications and requirements.

Industry Standards

Our certifications and ratings ensure that our tape-wound core products and processes meet customer and industry standards. We guarantee to comply with these various standards for better customer satisfaction.

Our industry standards:

- ISO 9001

- RoHS

- REACH

- EIA Standard RS-217

- ASTM (compliant)

- ANSI (compliant)

- ITAR

- DFARS

- Mil-Spec (compliant)

We assure you that our products are manufactured with quality in mind. Our exceptional craftsmanship allows us to manufacture cores that exceed your expectations while being cost-effective and efficient.

Work with Us to Obtain the Magnetic Cores You Need for Your Projects

The magnetic cores we produce are everything you need to achieve optimal performance for different operations. These are products that will ensure you experience successful projects in your industry.

So if you need any help or have any questions, don’t hesitate to contact us today. You can also request a quote, and we’re happy to work with you every step of the way.