STANDARD & CUSTOM TAPE WOUND SOFT MAGNETIC CORES

As an industry leader in the design and manufacturing of tape wound soft magnetic cores, at MK Magnetics, Inc. we are in a unique position to identify industry trends and changing customer needs. Early on in our history, we recognized a deficiency within the industry for custom manufactured tape wound soft magnetic cores. Although our lines of standard products are extensive, the increasing shift towards custom designs was an area of that required a solution. To accomplish this, MK Magnetics assembled a team of highly experienced tape wound core veterans with the goal of augmenting standard cores with highly customizable products. Superior Engineering and Customer Service Support are an inherent part of this process which allows MK Magnetics to manufacture cores that provide maximum performance. From innovative engineering to cutting edge materials such as nanocrystalline, various amorphous materials, 3% grain-oriented and 6.5% non-oriented silicon steel, 50% and 80% nickel materials, Supermendur, and many other highly specialized materials.

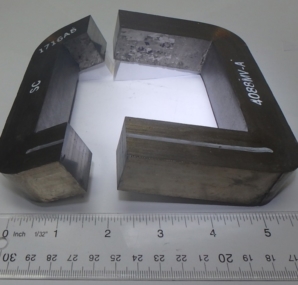

Another key advantage of this service is the flexibility of MK Magnetics manufacturing capabilities. Within our facility, we can build cores weighing from .002 up to 4,000 lbs. +, and in dimensions up to 7.5’ in height by 4’ in width, depending on overall geometry. They can be configured as C, E, and pie type D-cores, cased and uncased toroid, bars, and a variety of custom shapes. We also have the flexibility and expertise to develop custom processes to accommodate virtually any core design with no restriction on volume. This is comprehensive offering and is backed up by a robust quality program and a full range of in-house testing capabilities, providing compliance with various industrial standards. MK can typically begin delivering in 3-5 weeks with expedited deliveries available.

For more information, please see the table below or contact us directly.