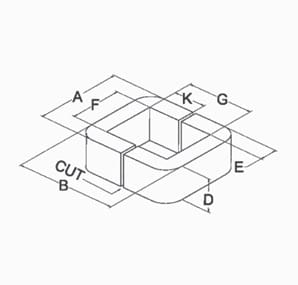

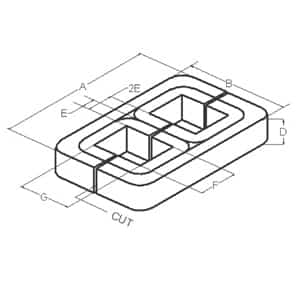

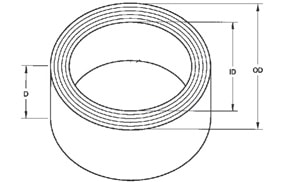

Dimensional Tolerances for Cut C-Cores, Cut E-Cores & Toroids

There are many magnetic cores available, each of which is designed and built to distinct specifications to suit different applications. If you are a design engineer or purchasing agent for a manufacturing company, it is important you choose the right magnetic core solution for the intended application. Otherwise, it may not work as intended in the manufactured assembly.

One of the key factors to keep in mind during the core selection process are the dimensional tolerances. Dimensional tolerance refers to the permissible range of dimensions for a particular type of magnetic core. While these values may vary depending on the core’s shape, material type, and material thickness, they indicate the minimum and maximum size it can be to remain compliant with the manufacturing project’s requirements and restrictions. If any dimension falls outside of this range, the core is not compliant and not suitable for use in the particular manufacturing project. Some magnetic component applications are so sensitive that even a variance of less than .003 inches cannot be tolerated.

Looking for a supplier you can trust to deliver magnetic cores that meet your dimensional tolerance demands? Turn to the experts at MK Magnetics! We can design and manufacture components that will accommodate nearly any pre-fab coil and fit into some of the tightest spaces. Whether you need industry-standard or tighter tolerances, we have what it takes to provide a core solution that fits optimally within your device. Below, we highlight our magnetic core offerings.